MULTI ENGINEERING DEPARTMENT

"ACCORDING TO CUSTOMER SPECIFICATIONS"

Nakaya Seisakusho Co., Ltd.'s Equipment Technology Department uses an integrated production line to manufacture products according to customer specifications, from conceptual design to processing, assembly, and installation.

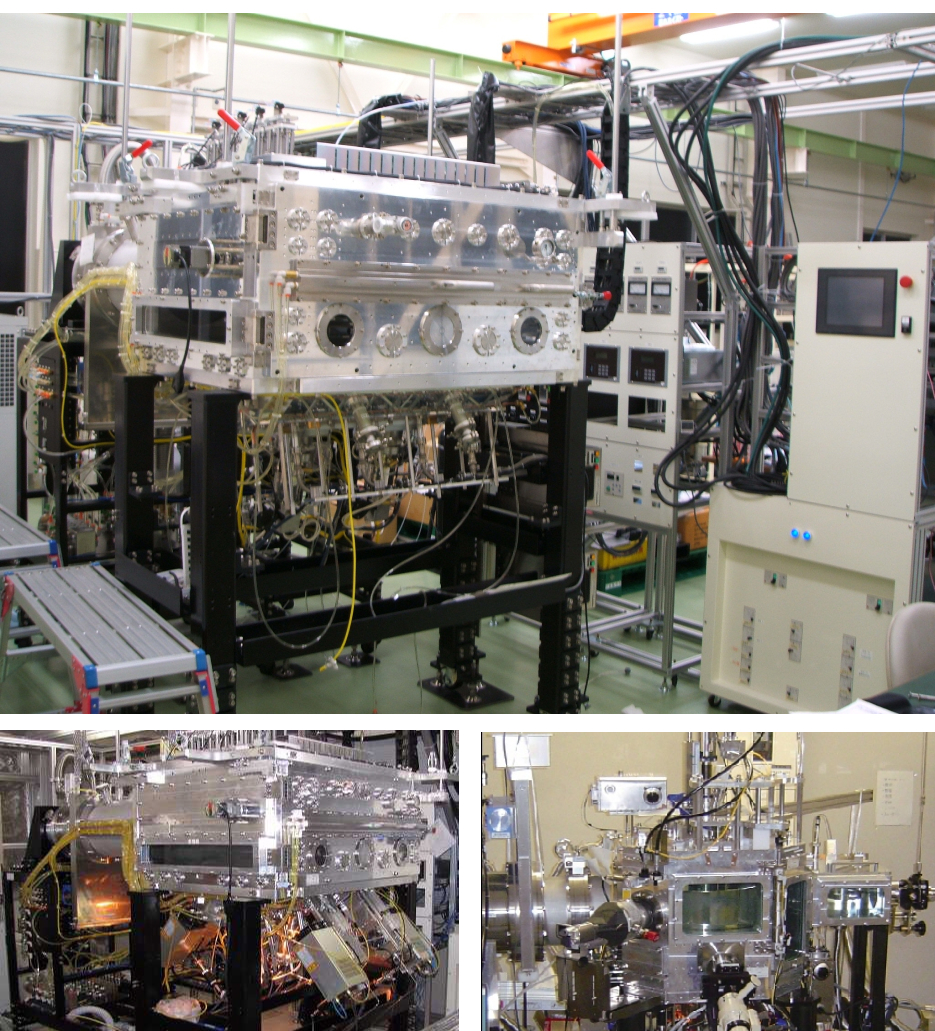

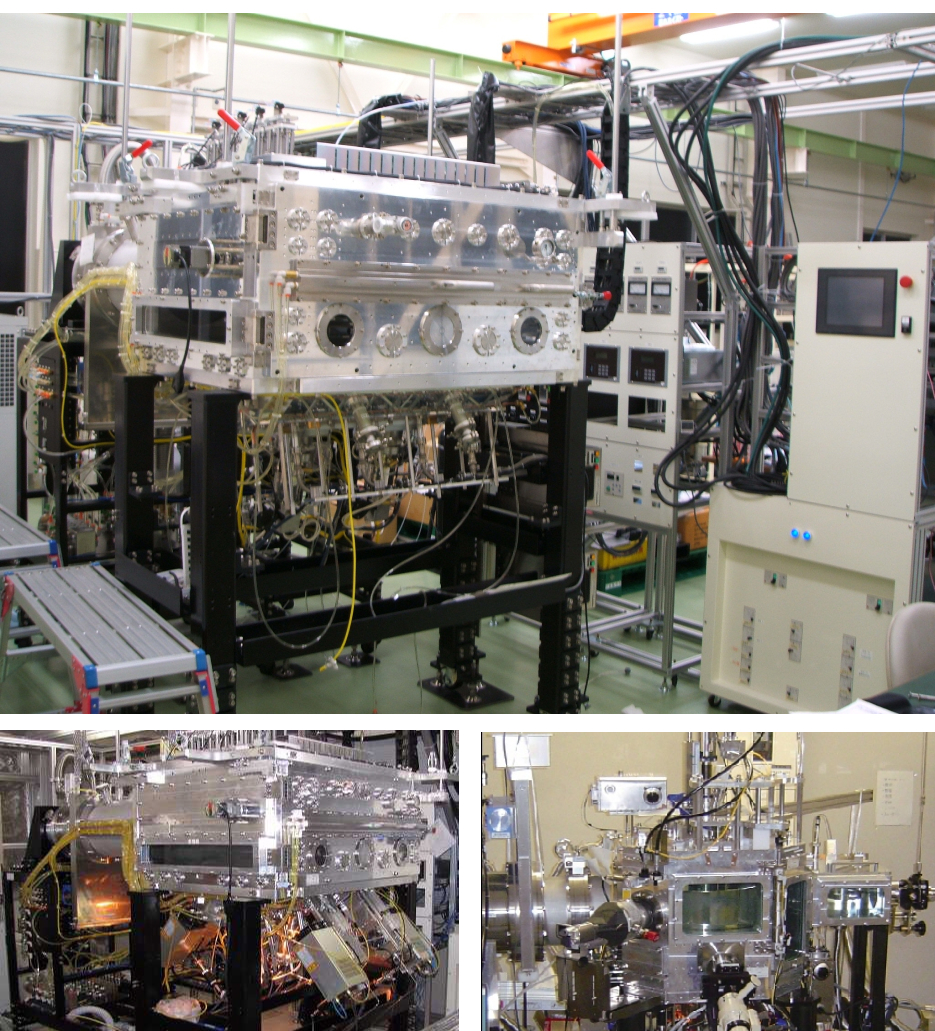

Roll to Roll Method Zinc Oxide Film Deposition Equipment NFD101

In June 2014, we developed an "RTR method zinc oxide film deposition system." In addition to providing rare metal-free and low-cost transparent conductive films, we are now able to provide flexible transparent conductive film substrates that are easy to measure, inexpensive, and provide flexible devices such as PV and FPD that are expected to grow in the future. This is Nakaya Seisakusho's Only One technology:

① High-quality oxide film formation technology using plasma-assisted deposition method (patented in Japan, the United States, and Europe).

②

A space-saving design and high maintainability are realized by the RTR film transport method and the arrangement direction of the raw material sources (patent pending).

③

Assembly-type vacuum chamber that achieves high precision and high airtightness at low cost and short lead time (patent pending).

Here is Nakaya Seisakusho's Best One technology:

①

High airtightness is ensured by processing the vacuum seal surface using a unique method.

②

Operability focused on user needs.

③

By developing our own film-forming quality inspection equipment, we provide total support from manufacturing technology to quality confirmation.

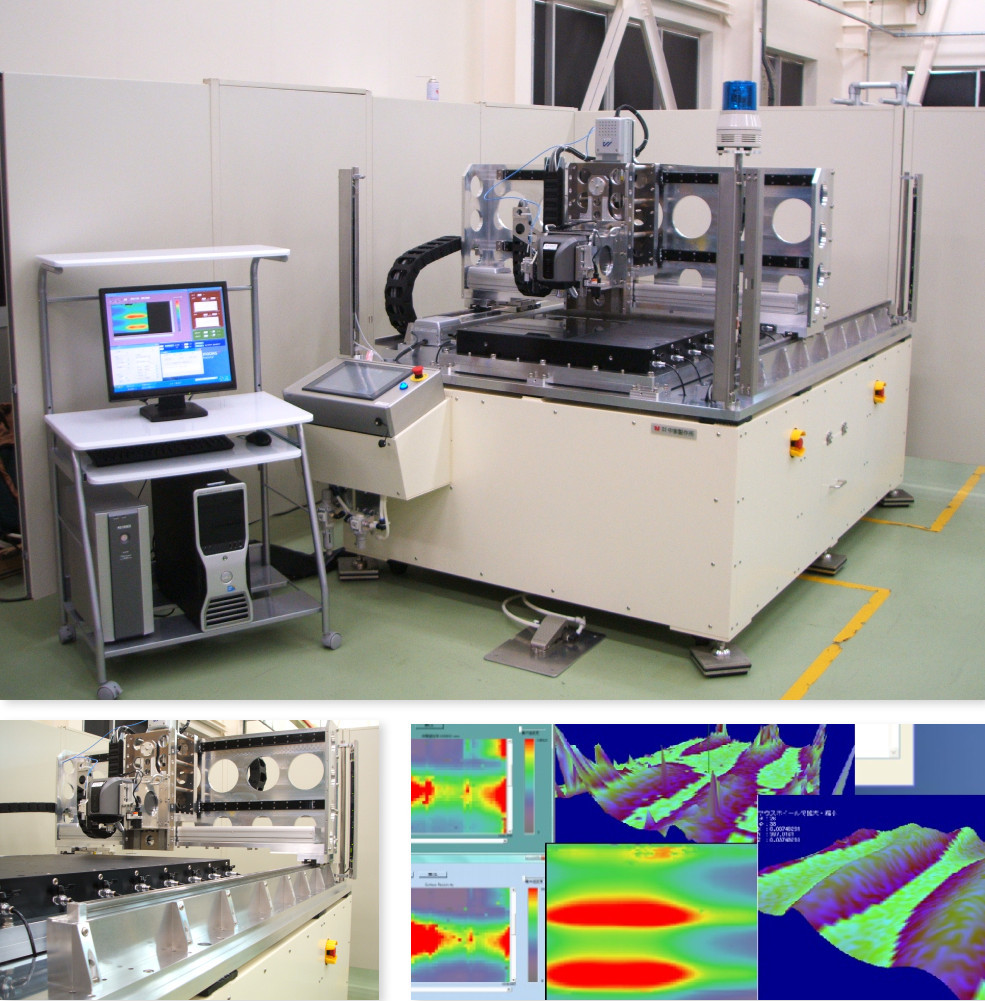

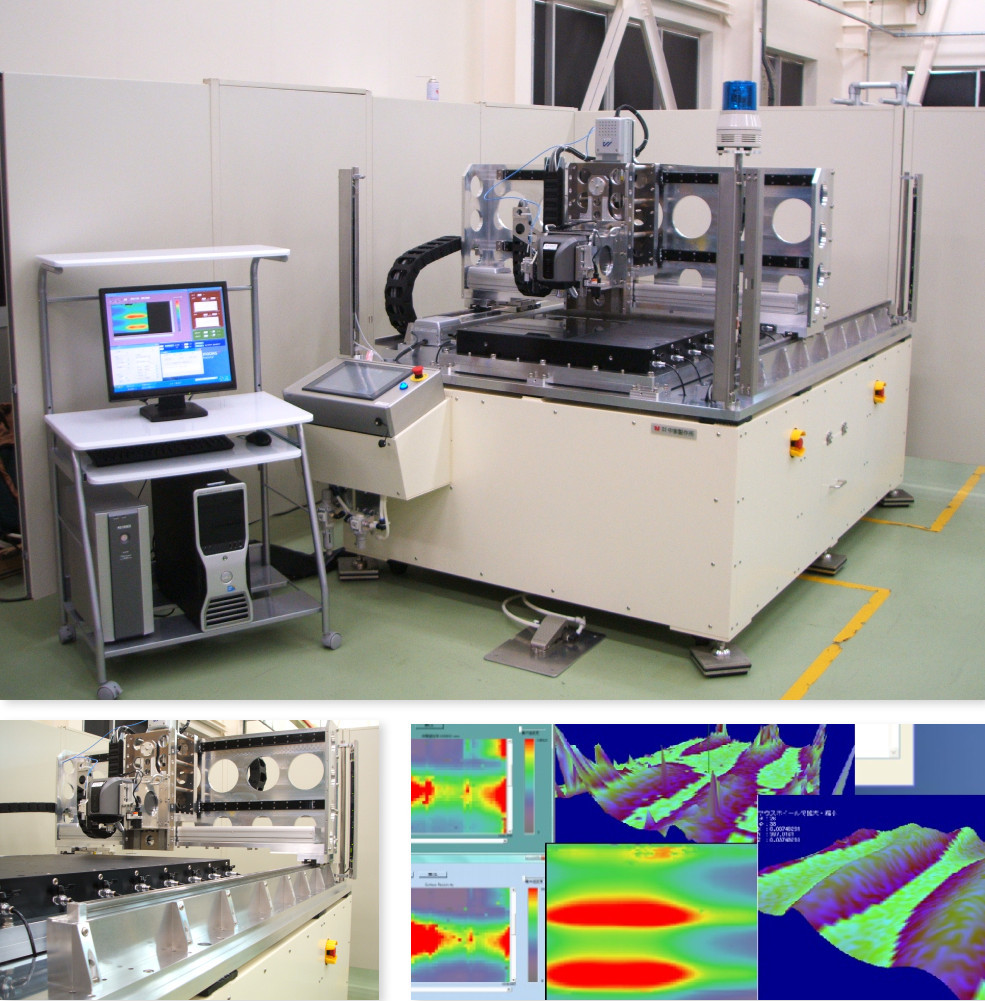

Film Quality Inspection Device NFT001

In July 2011, Nakaya Seisakusho Co., Ltd.'s Equipment Technology Department developed the NFT001 (NAKAYA FILM TESTER001), a film quality testing device that can non-destructively inspect film-formed substrates. Conventionally, film quality inspections were done destructively, but we thought it would be possible to do it non-destructively. Therefore, NFT001 was developed. This is an inspection device that is equipped with a film thickness meter, resistivity meter, and laser microscope in the head part, making it possible to measure film thickness, resistivity, and particle counter, and display the data in 3D mapping. In addition, HEIZ (cloudy) measurement can be performed at the same time. (approximation)

Research and Development Project

Another equipment technology department project. The Equipment Technology Department of Nakaya Seisakusho Co., Ltd. is conducting research and development on next-generation film deposition, and is developing a GZO transparent conductive film deposition system. The film currently used is mainly products with a film called ITO. However, in recent years, indium, which is necessary for ITO, is in danger of being depleted and is very expensive (a rare metal). This development has been carried out through collaboration between industry, academia, and government since 2004, and was taken up as a support industry project in 2006, and research and development is currently progressing to the point where it is on par with ITO film formation. The Equipment Technology Department of Nakaya Seisakusho Co., Ltd. will focus on research and development of GZO transparent conductive film deposition equipment in anticipation of this next-generation film deposition demand.